PARTICIPATION AT THE HEART OF YOUR PROJECTS

FOR YOUR PROCESS PERFORMANCES

Specialized in engineering consultancy for over 15 years, Maser Engineering capitalizes on its experience in the field to propose an offer adapted to client expectations. Engaged in a continuous improvement approach, our team of experts fully participates in the optimization and performance of industrial processes. For a more connected, optimized and creative industry, Maser Engineering also supports its clients in meeting the challenges of the digital world.

AN OFFER ADAPTED

TO EVERY NEED

Maser Engineering acts in all the process life cycle phases and in particular industrialization and production.

On the one hand, by providing technical support or project management support in the main innovation and R&D, management, project management, and production and maintenance performance improvement fields. On the other hand, by proposing a global offer that combines concepts from Lean Manufacturing and Industrial Ergonomics benchmarks.

Our teams also take part in technology transfer, the definition and inspection of quality processes, and supervise the implementation of offshore engineering and production activities.

INDUSTRIAL METHODS AND PROCESSES

Measuring and controlling quality, cost and deadline factors are a source of productivity which makes it possible to anticipate the economic and organizational performance of your business. On this subject, our team studies areas for improvement, modernization and upgrade to compliance of your manufacturing and assembly processes.

- Project management, industrial resource acquisition

- Definition of industrial methods and processes

MAINTENANCE

MANAGEMENT

Our team defines, implements, checks and optimizes industrial asset management in order to increase resource availability and reduce operating costs.

- Maintenance

- Asset management

- Maintenance support

- Safety and risk management

LOGISTICS MANAGEMENT (SUPPLY CHAIN)

We help manage all the resources, means, methods, tools and techniques used to manage your global supply and delivery chain as efficiently as possible.

- Purchasing strategy and supplier panel management

- Competition management, negotiation and contracting

- Supplier complaint management

- Technical and contractual support in industrial maintenance process organization

DATA

MANAGEMENT

In an increasingly connected industrial environment, our industrial engineering experts design and implement IS architecture and processes used to collect, store, use and secure your data. We offer IT solutions adapted to your actual needs.

- Industrial process analysis

- Information system analysis

- Proximity to production units

- Interactive developments and modular solutions

INDUSTRIAL ERGONOMICS AND LEAN MANUFACTURING

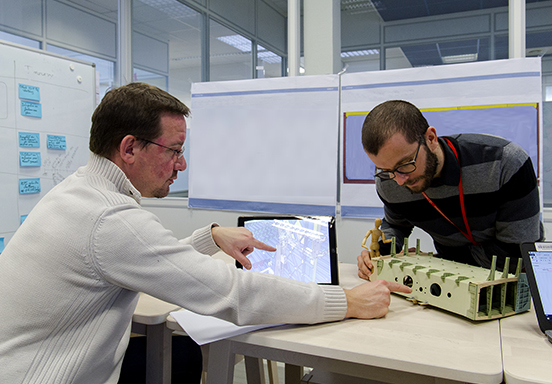

By your side, Maser Engineering consolidates your company’s strategic directions by supporting you in the search for improvement solutions. We assist you in the operational implementation of innovative action plans which combine Lean Manufacturing and Industrial Ergonomics and ensure their effectiveness over time through the use of management indicators.

Our team of experts is involved in change management through coaching actions for a better acceptance of your progress policies. If the purpose of our interventions is the search for efficiency, we make team spirit and collaborative work the vectors of success.

INDUSTRIAL ERGONOMICS

Maser Engineering makes sure of the best compromise in adapting production workstations and proposes a global and complete approach considering both the search for efficiency and the risks of hardship.

- Frequency rate / severity rate (Fr ; Sr)

- Risk of muscular-skeletal disorders (MSD)

- Psycho-social risks (PSR)

- Human Machine Interface (HMI)

- Disability

LEAN MANUFACTURING

Maser Engineering guarantees ideal operating conditions, reducing sources of performance loss and non-added-value, reducing waste and losses.

- Excess production

- Excess or unnecessary stock

- Unnecessary transport and travel

- Excess or unnecessary processing

- Unnecessary movements and congestion

- Errors, faults, rejects

- Waiting time, delays

OUR MISSION

IN A FEW POINTS

Rigorous and committed technicians and engineers for the effective management of your projects.

-

ANTICIPATION

Confirmed feedback for better measurement and anticipation

-

METHODOLOGY

Precise methods adapted to needs

-

CONTROL

Teams with perfect mastery of multiple fields and sectors

-

INNOVATION

An innovating approach and technological transition support

-

RESULTS

Qualified experts with a duty of means and results

-

IMPROVEMENT

Employees seeking continuous improvement